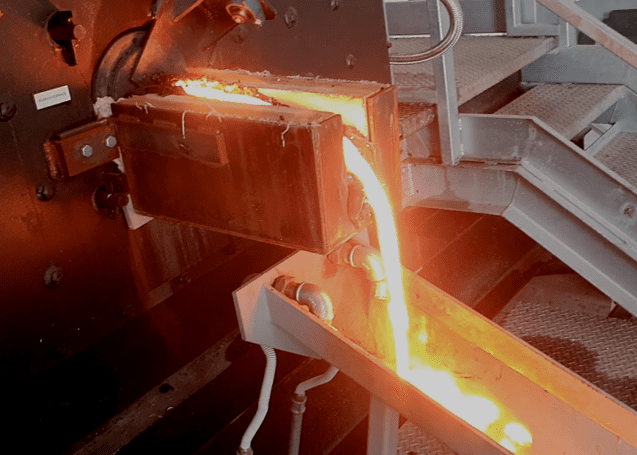

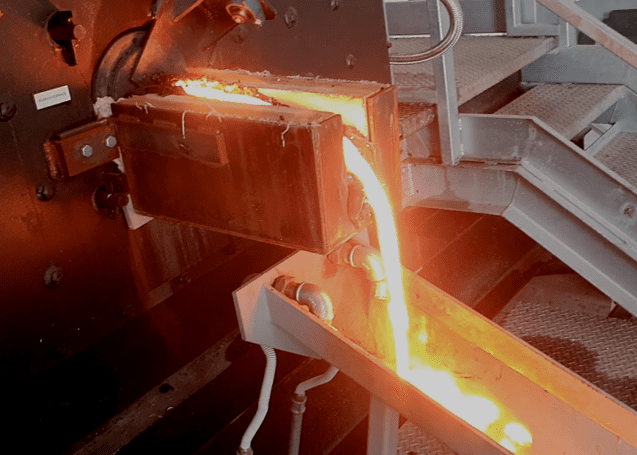

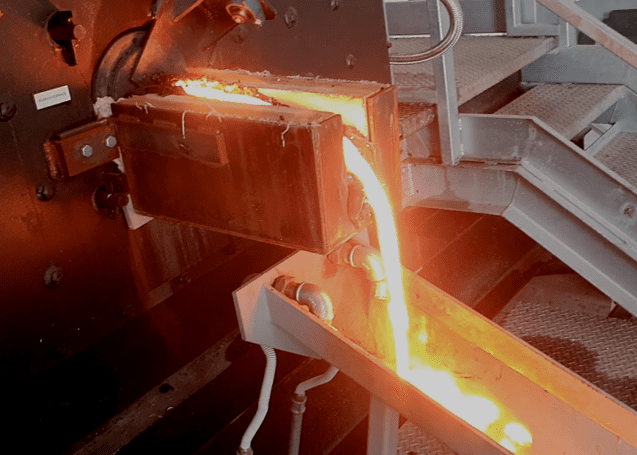

// SBM furnace for //

Reinforced fiber recycle material

// SBM furnace for //

Glass cullet recycle plant with organic content and few metallic inclusions

// SBM furnace for //

Recycling of all TV cathode ray tube and cristal type glass -with high content of led

// SBM furnace for //

Recycling of Hydroponic waste made of stone wool blocks full of organic material

// SBM furnace for //

Recycling of wet waste

// SBM furnace for //

Small granulometry coke recycling coming from metallurgic cupola production line